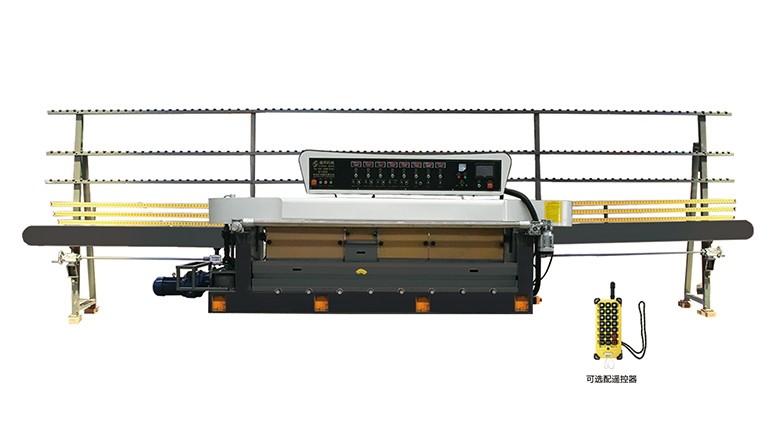

The machine is variable frequency speed regulation, No. 1, No. 2 forming motor 5.5 kW, No. 3, No. 4 polishing motor 4 kW, No. 5 motor 3 kW (1-5 good motor flat), No. 6 motor 3 kW (vertical) , the motor can be moved to the smooth surface of the plate to process the stair anti-skid groove, or it can be moved to the bottom of the stone to process the flat edge to remove the wire. The machine base independently researches and develops a single-guide column structure, which can be locked after adjusting the position of the grinding wheel motor. It can be equipped with a grinding wheel with a diameter of 18 cm, and the guide rail can be lifted and lowered synchronously. According to different stone sizes, the thickness is within 8 cm and the height is more than 6 cm. Grinding various flat stone sizes Round edge, French edge, R round belt side throwing, stair opening, anti-skid belt, polishing belt, linear shape completed at one time, grooved polishing Slotted polishing is counted as various special-shaped edges, rough grinding, fine grinding, and polishing processes are completed at one time, and the brightness after processing is high. Due to the brightness of the board surface and the wear and tear of the polishing grinding wheel, the grinding wheel can electrically adjust the abrasive lifting during operation to compensate. It has an advanced and reasonable structure, high precision, fast efficiency, convenient operation, and simple maintenance, and the feed can be adjusted during the grinding process. The speed and the amount of processing, the maximum processing of 5m/min, the normal use of the machine are equivalent to the normal stone processing of 15 people's workload, and to eliminate the process defects caused by workers during processing.

vertical edging machine 8512