Description:

LD2200 is a new type of automatic PET bottle blowing machine. The machine uses the touch screen as the operation interface and PLC programming controller for action arrangement, which can control and feed back the whole production process. It has the function of remote debugging. It is an upgraded product of pet pet bottle making machinery.1. the first mock exam bottle can be used in each device, and 2000-2500 bottles per hour (14 grams of 500ml bottle), the maximum can be blown to 2 liters.

Features:

I. the first mock exam bottle can be used in each device, and 2000-2500 bottles per hour (14 grams of 500ml bottle), the maximum can be blown to 2 liters.

II. only high-pressure gas is used without purchasing low-pressure supporting system. All low-pressure gas, including pre-blowing, adopts high-pressure recovered gas.

III. The biggest feature of the equipment is energy saving, which can save about 40% per hour under the same output. The energy-saving mode is mainly reflected in the following four aspects:

(a) increase the bottle blowing speed.

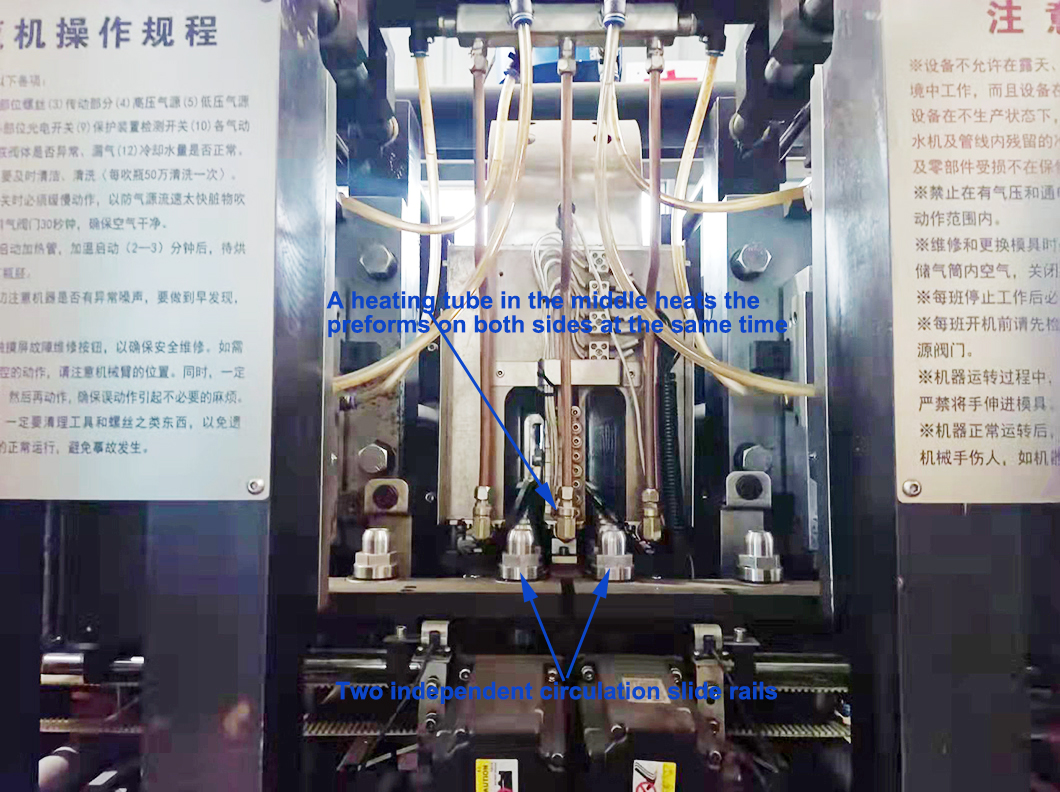

(b) there is only a row of heating tubes in the middle of the lamp box, and the bottle embryos are circulated on both sides, with dense intervals to maximize the use of heat.

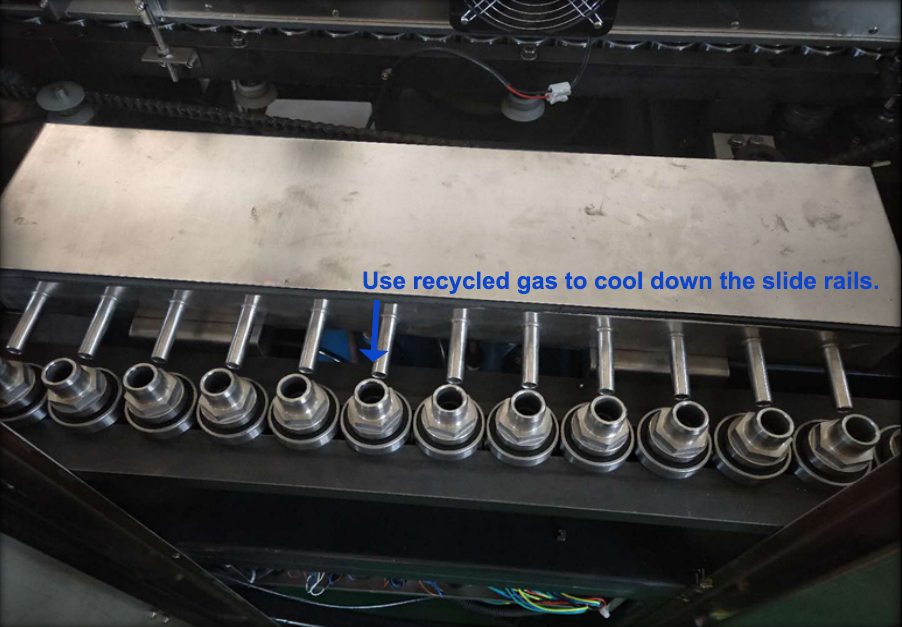

(c) save the power consumption of low-pressure supporting system (all low-pressure gas, including pre-blowing, all use recycled gas).

(d) the cooler system can run only after a short warm-up.

IV. The whole machine covers a small area and saves space. The preform hoist is inside the equipment, and the hopper is of push-pull design, which is convenient for operation, and the overall structure is compact and practical.

Specification:

Model | LD2200 | |

Cavity | pc | 1(max bottle size 2L) |

Capacity | bph | 2000-2500(14g/500ml bottle) |

Bottle diameter | mm | ≤108 |

Bottle height | mm | ≤310 |

Bottle neck diameter | mm | 26-38 |

High pressure gas consumption | L/min | 1.4m³/min(500ml bottle) |

Suggested air pump | L/min | 1.6m³/min |

Operation pressure | Mpa | 25-30 |

Blow pressure | Mpa | 2.5-6 |

Water cooling pressure | Mpa | 0.3-0.5 |

Cooling water temperature | ℃ | 12-20 |

Rated power | kW | about 3-5KW(main motor power) |

Rated voltage | V | AC 380 50HZ |

Overall dimension | mm | L2160xW1160xH2000 |

Requirements for operating ambient temperature | ℃ | 5-40 |

working environment Humidity requirements | %rh | ≤80% |

Product Photos:

1. The bottle discharging and bottle preform heating device adopts the setting of public baking bottle preform. The bottle discharging direction is on both sides of the machine. There are separate tracks on both sides to run forward with the bottle preform. The heating device is in the middle of two slide rails. It adopts a new design. One heating device is shared by two slide rails to maximize the use of energy.

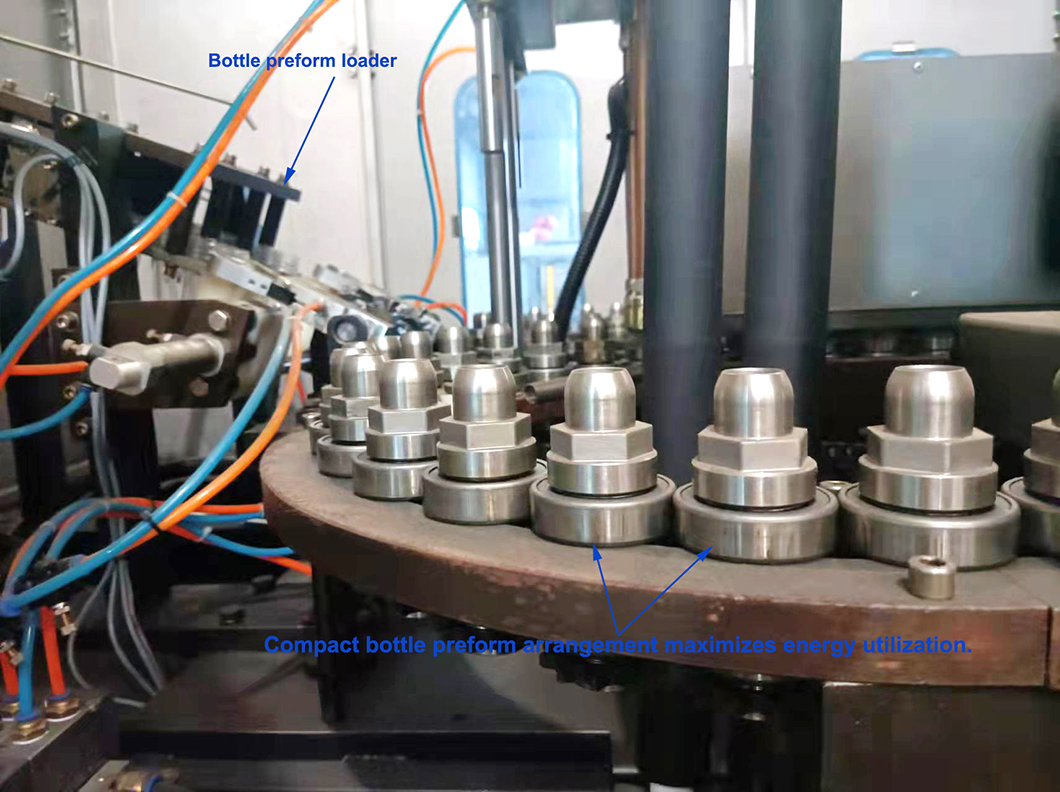

2.Compact bottle preform arrangement to achieve maximium utilization of the heating energy.

2.Compact bottle preform arrangement to achieve maximium utilization of the heating energy.

3.Two groups of light boxes using separate box temperature control maximum use of the light and heat, and use recycled gas to coll down the slide rails.It save the cost of low pressure device and save the energy consumption of the low pressure device as well.

4.The whole machine covers a small area and saves space. The perform hoist is inside the equipment, and the hopper is of push-pull design, which is convenient for operation and compact and solid overall structure

Factory profile:

Contact: