- Output (kg/h):

- 150 - 1000 kg/h

- Screw Speed (rpm):

- 1 - 100 rpm

- Screw Speed:

- 0~115RPM

Product Overview

PP PE PET Recycle Plastic Granules Making Machine Recycled Plastic Pellet Production Line

Plastic Pelletizing and Granules Making Machine

1,High practicable for kinds of waste plastics recycling like plastic films, sheets and style material. 2,Equipped with non- stop

filter net hydraulic changing for high automation and better output.

3,Particular features have granules from this machine with good plastic performance.

Cold Cutting pelletizing way

Suitable for hard plastic flakes

Easy to operate

High Capacity

PRODUCT CONFIGURATION

1.Dosing feeder

Dosing feeding the material into exturder

Keep the exturder more stable working

Speed adjust by inverter

Hopper made by stainless steel

2.Single Screw Extruder

Single screw Extruder made by sturdy frame, heavy. No vibrating when machine running; The whole frame where installed the gearbox,

motor and screw has done the milling working. The frame is build up by the square tube and thick steel on top.

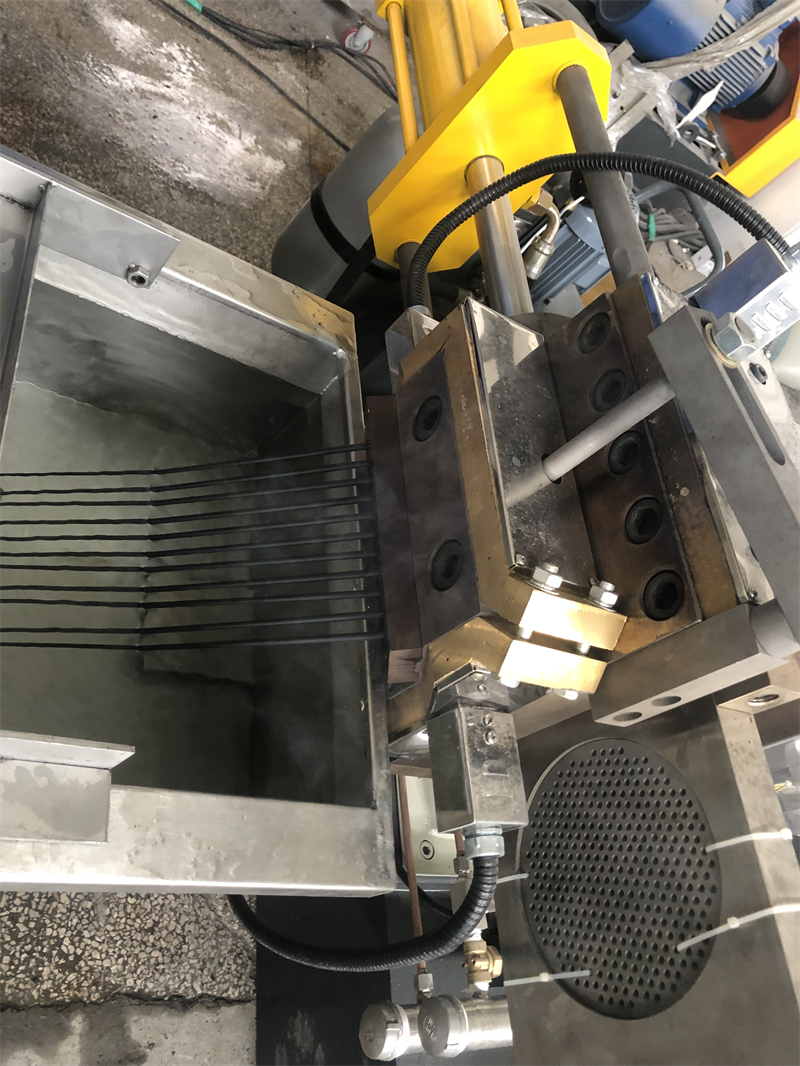

3.Hydraulic Screen Changer

Double position board model Board made by 38CrMnAl with forging, heating treatment won’t deform after heating using.

4.noodle cutting

5.Cooling Tank.

stainless steel

6.Cutting Machine

7. oil recycling system

8.Plastic granules

size: Φ 3X3mmthe size can be adjsut by the dic face cutter speed

9..Electrical control cabinet

>>All electrical units mounted in a strong safe electrical cabinet;

>>Safety interlock principle applied in the system;

>>Inverter: ABB/FUJI/DELTA;

>>Contactor: Schneider;

>>Adopt CE safety electrical components;

>>Solid state relay is optional for heating control.

PRODUCT SPECIFICATIONS

第1年

第1年

PE PP PETWaste Plastic Crusher

PE PP PETWaste Plastic Crusher

Plastic Film Squeezer Machine

Plastic Film Squeezer Machine