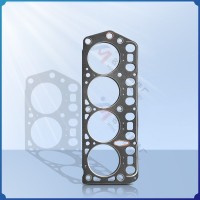

重卡车气缸体是构成发动机的重要部件之一,它的作用是容纳活塞和与之配合的活塞环、压缩室和火花塞等,并且提供了进气、排气和冷却等通道,以保证发动机正常运转。

安装气缸体的方法如下:

第一步:清理油垢和灰尘,检查气缸盖和气缸套的表面是否光滑,确保没有凹痕或损坏。

第二步:向气缸体通入适当的润滑油,并保证气缸壁表面的光滑度。

第三步:将气缸套放入缸孔中,并使其与气缸盖完全吻合。使用一个活塞头,轻轻地敲打套筒,并使其与气缸盖深度一致。

第四步:将活塞装入气缸套,注意活塞环必须平稳地通过缸套。

第五步:安装气缸盖并拧紧螺栓,确保安装位置准确,螺栓力度均匀,必要时使用扭矩扳手。

拆卸气缸体的方法如下:

第一步:放松气缸盖上的所有螺栓。

第二步:拆卸气缸盖,注意不要损坏内部部件,同时应该避免将部件掉落到底部。

第三步:将油在发动机的下方放空,并放过水和冷却剂。

第四步:用扳手拆下所有气缸体螺栓。

第五步:谨慎地将气缸体和底板分离,注意不要损坏底板的盖子或其他部件。同时,拆卸过程中要注意安全,避免气缸体跌落造成伤害。

在安装和拆卸气缸体时,需要注意以下要求:

1.必须按照厂家的规定和指导书进行操作,避免出现操作错误。

2.在拆卸时,必须使用适当的工具和设备,并遵循安全规程,避免发生事故。

3.在安装时,必须使用适当的螺栓和垫片,确保安装位置准确,并避免泄露。

4.在操作过程中,必须保持清洁和干燥,保护气缸体和其他部件的质量和性能。

总之,安装和拆卸重卡车气缸体需要注意一定的技术和安全要求,操作过程中务必仔细、细心、耐心,并遵循相应的规程和标准,

以确保操作的成功和质量。

The heavy truck cylinder block is one of the important parts of the engine. Its function is to accommodate the piston and the piston ring, compression chamber and spark plug, etc., and provide air intake, exhaust and cooling channels to ensure the normal operation of the engine. run.

The method of installing the cylinder block is as follows:

Step 1: Clean up grease and dust, check that the surface of the cylinder head and cylinder liner is smooth, and make sure there are no dents or damage.

Step 2: Inject proper lubricating oil into the cylinder block and ensure the smoothness of the cylinder wall surface.

Step 3: Put the cylinder liner into the cylinder bore and make it fit the cylinder head completely. Using a piston tip, tap the sleeve lightly to the depth of the cylinder head.

Step 4: Install the piston into the cylinder liner, and pay attention that the piston ring must pass through the cylinder liner smoothly.

Step 5: Install the cylinder head and tighten the bolts to ensure that the installation position is accurate and the bolts are evenly tightened. Use a torque wrench if necessary.

The method of removing the cylinder block is as follows:

Step 1: Loosen all bolts on the cylinder head.

Step 2: Remove the cylinder head, taking care not to damage the internal components and avoid dropping the components to the bottom.

Step 3: Drain the oil under the engine and let the water and coolant go.

Step Four: Use a wrench to remove all cylinder block bolts.

Step Five: Carefully separate the cylinder block from the base plate, being careful not to damage the cover or other parts of the base plate. At the same time, pay attention to safety during the disassembly process to avoid injury caused by the cylinder block falling.

When installing and removing the cylinder block, the following requirements should be paid attention to:

1. It must be operated in accordance with the manufacturer's regulations and instructions to avoid operating errors.

2. When disassembling, proper tools and equipment must be used, and safety regulations must be followed to avoid accidents.

3. When installing, proper bolts and gaskets must be used to ensure accurate installation position and avoid leakage.

4. During operation, it must be kept clean and dry to protect the quality and performance of the cylinder block and other components.

In short, certain technical and safety requirements must be paid attention to when installing and dismantling the cylinder block of heavy trucks. Be careful, careful, patient, and follow the corresponding regulations and standards during the operation.

To ensure the success and quality of operations.

第1年

第1年

重卡发动机Heavy truck engine

重卡发动机Heavy truck engine

重卡车原厂皮带 truck original bel

重卡车原厂皮带 truck original bel

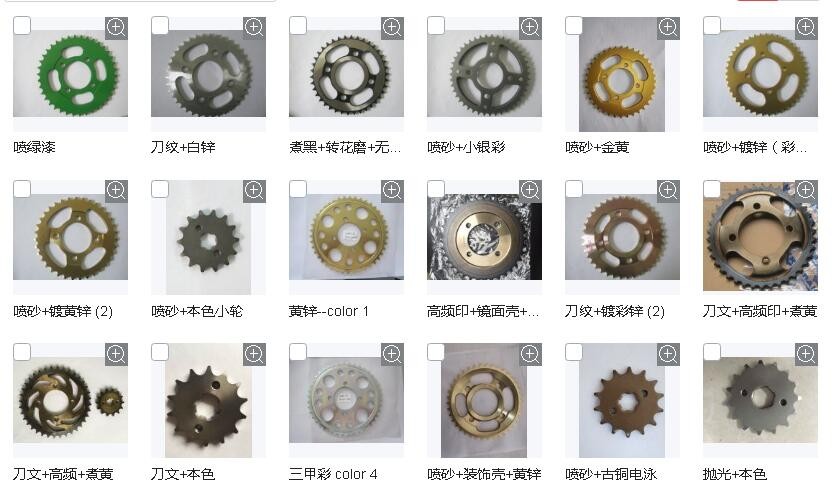

四/五配套Four and five packages

四/五配套Four and five packages

重卡车型种类/Types of heavy truck

重卡车型种类/Types of heavy truck

重卡驾驶室/Heavy truck cab

重卡驾驶室/Heavy truck cab

飞轮壳/flywheel housing

飞轮壳/flywheel housing

重卡车轴承/Heavy truck bearings

重卡车轴承/Heavy truck bearings